About Us

About Raltor Metaltechnik India Private Limited

Raltor Metaltechnik India Private Limited was incorporated in the year 2006 with the mission to offer high quality products and services that exceed client’s expectations. From inception our consistent efforts towards manufacturing products of top notch quality has made us to touch new horizon.

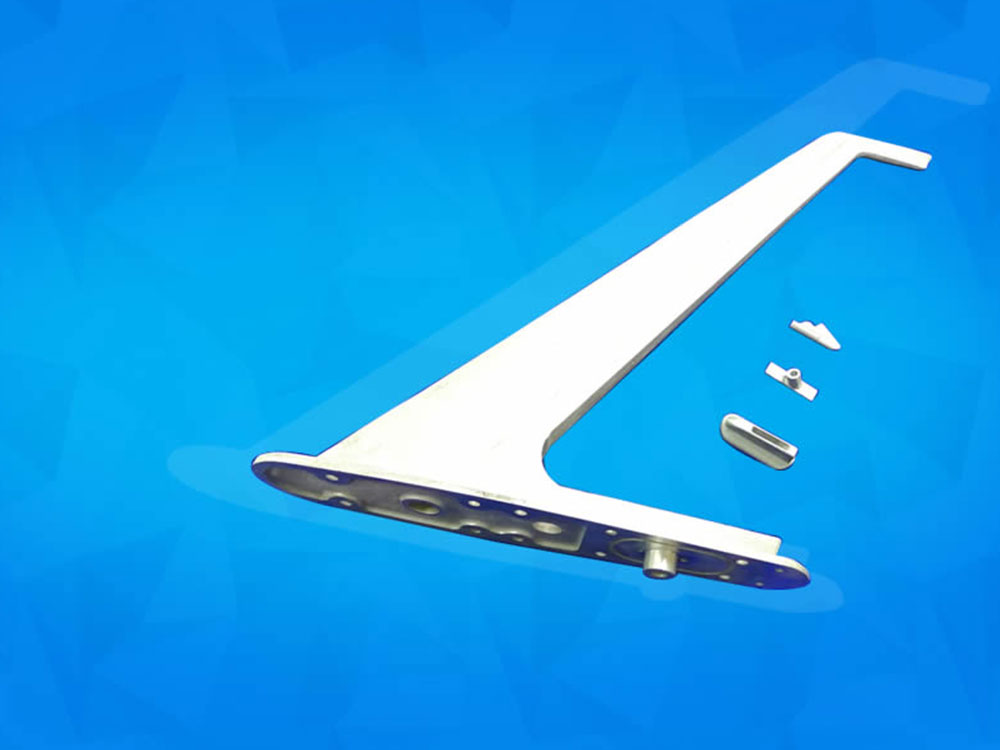

The product range that caters to varied industrial needs comprises of Aluminium and Zinc Pressure die casting and sub-assemblies. Raltor has progressed well and today its products include Telecom , Electrical , Motors , Automotive , Chemical , Valves , Textile , Wind mills ,Aerospace , and VMC / CNC machined component serving the needs of, above mentioned industry’s.

Raltor a new symbol of Quality

Raltor Metaltechnik India Private Limited was incorporated in the year 2006 with the mission to offer high quality products and services that exceed client’s expectations. From inception our consistent efforts towards manufacturing products of top notch quality has made us to establish our self as one of the fastest growing manufacturer and supplier of Aluminium and Zinc Pressure Die Casting ,CNC /VMC Machining and Sub-Assemblies.

Raltor has progressed well and today its product range include Aluminum and Zinc castings , Forged components, Motor and Valve parts, Automotive parts, Plastic parts, Oil and Rigs parts, ,Medical Equipment Assembly, Wind Mill Components, Telecommunication Equipments and Telecom Components.

Vision

RALTOR’s Corporate Vision is to be a “World Class Die Casting Company”, for serving Domestic and Export to meet their requirement in terms of Quality , Cost , Timely Delivery.

Mission

"Raltor aims to be the reliable partner by maintaining a superior level of integrity in interactions with business partners across the globe. Leveraging our expertise we always make continual improvement to offer high quality products and services that exceed client’s expectations. "

Values

Creating business value through Operational Excellence, Serving Customers for Life

Why Choose Us?

-

On Time Delivery

-

Superior Product Quality

-

Comprehensive Customer Service

-

Competitive Pricing

-

Good Logistic support

Our Quality Policy

Our wide range of Industrial Components, Aluminium Castings & assemblies; tools & jigs and forged, CNC and VMC machined components and sourcing of all Engineering Components has become the preferred choice for our esteemed clients owing to its high quality standards. We make sure that our products are tested stringently on various parameters at every stage of production. Our quality experts use all the latest testing facilities in our testing unit, which is kept in hygienic conditions thus; ensuring hassle free inspection.

We execute the tests in the following stages:

Stage 01

We inspect the raw material at the manufacturer’s premises to gauge its suitability for the production

Stage 02

We inspect the production process closely to ensure the products meeting the specific requirements

Stage 03

We conduct the visual inspection of our finished output before dispatching it to the clients

Building trust with employees, customers and community.